CALEDONIAN

Professional Cable Provider

Quick Contact

The cables are suitable for reeling power supply cables for TBM’s machines and in underground mines for tunnel constructions.

| Construction | DIN VDE 0250-813 |

| General Requirements | DIN VDE 0250-1 |

| Guide Use | DIN VDE 0298-3 |

| Electrical Tests | DIN VDE 0472-501, 503, 508 |

| Non-Electrical Tests | DIN VDE 0472-401. 402,602,303, 615 |

| Under Fire Condition Tests | DIN VDE 0472-803, 804 |

| Flame Retardant | VDE 0482-332-1-2,DIN EN 60332-1-2,IEC 60332-1 |

| Oil Resistant | HD/EN/IEC 60811-2-1.,DIN VDE0473-811-2-1 |

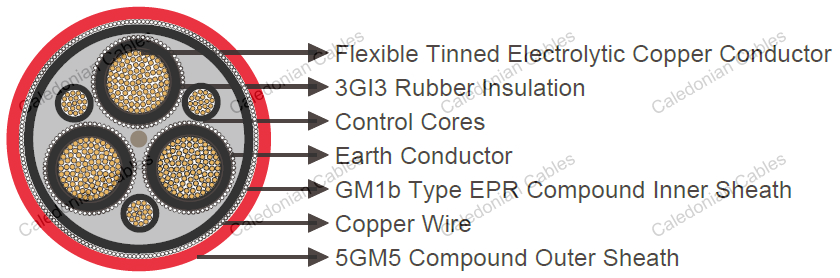

Conductor : Flexible Tinned Electrolytic copper conductor DIN VDE 0295 Class 5.

Insulation : 3Gl3 type EPR compound.

Electrical Field Control : Inner and Outer semiconductive layer of semiconductive rubber.

Control core : Tinned Copper conductor with semiconductive layer.

Protective-Earth Conductor : Tinned Copper/ Textile braiding combinated cores laying concentric around each power core.

Core Identification

Main Cores : Natural coloring with black semiconductive rubber.

Control cores : Black.

Lay Up : Three main conductors laid-up with three control cores in the outer interstice.

Inner Sheath : GM1b Type EPR Compound.

Screen Overall : concentric lay of copper wire spinning.

Outer Sheath : 5GM5 Type elastomer compound. Red.

| Rated Voltage | 3.6/6 KV | 6/10 KV | 8.7/15KV | 12/20 KV | 18/30 KV |

| AC Test Voltage | 11KV | 17KV | 24KV | 29KV | 43KV |

| Max.Permissible Operating Voltage AC | 4.2/7.2 KV | 6.9/12KV | 10.4/18 KV | 13.9/24KV | 20.8/36 KV |

| Max.Permissible Operating Voltage DC | 5.4/10.8 KV | 9/18 KV | 13.5/27 KV | 18/36 KV | 27/54 KV |

| Min Bending Radius | VDE 0298-3 Tab 3 | ||||

| Current Carrying Capacities | VDE 0298-4 | ||||

| Working Temperature | |||||

| Fixed | -40°C-+80°C | ||||

| Mobile | -25°C-+80°C | ||||

| Max.Tensile Load Of cable | 15N/mm² | ||||

| max.torsion | 25°/m | ||||

| Trawl Speed For Tunnelling App | Max.30 m/min | ||||

| Minimum Distarce For Change Of Direction | 20×D | ||||

| Cross Section | Overall Diameter (min-max) | Appro. Weight |

|---|---|---|

| mm² | mm | kg/km |

| 3x25+3x16/3E+3x2.5ST+6ÜLKON | 42.2-45.4 | 2770 |

| 3x35+3x25/3E+3x2.5ST+6ÜLKON | 46.8-50.0 | 3200 |

| 3x50+3x25/3E+3x2.5ST+6ÜLKON | 50.1-53.2 | 4040 |

| 3x70+3x35/3E+3x2.5ST+6ÜLKON | 54.6-57.7 | 5035 |

| 3x95+3x50/3E+3x2.5ST+6ÜLKON | 56.4-60.5 | 6270 |

| 3x120+3x70/3E+3x2.5ST+6ÜLKON | 64.0-68.0 | 7400 |

| Cross Section | Overall Diameter (min-max) | Appro. Weight |

|---|---|---|

| mm² | mm | kg/km |

| 3x25+3x16/3E+3x2.5ST+6ÜLKON | 45.5-48.2 | 2975 |

| 3x35+3x25/3E+3x2.5ST+6ÜLKON | 47.8-51.0 | 3420 |

| 3x50+3x25/3E+3x2.5ST+6ÜLKON | 50.7-54.9 | 4260 |

| 3x70+3x35/3E+3x2.5ST+6ÜLKON | 57.2-61.4 | 5270 |

| 3x95+3x50/3E+3x2.5ST+6ÜLKON | 61.1-65.3 | 6540 |

| 3x120+3x70/3E+3x2.5ST+6ÜLKON | 65.1-69.3 | 7840 |

| Cross Section | Overall Diameter (min-max) | Appro. Weight |

|---|---|---|

| mm² | mm | kg/km |

| 3x25+3x16/3E+3x2.5ST+6ÜLKON | 51.1-55.3 | 3600 |

| 3x35+3x25/3E+3x2.5ST+6ÜLKON | 54.0-58.2 | 4140 |

| 3x50+3x25/3E+3x2.5ST+6ÜLKON | 59.4-63.6 | 5030 |

| 3x70+3x35/3E+3x2.5ST+6ÜLKON | 64.2-68.4 | 6200 |

| 3x95+3x50/3E+3x2.5ST+6ÜLKON | 69.2-73.8 | 7520 |

| 3x120+3x70/3E+3x2.5ST+6ÜLKON | 73.6-77.8 | 8740 |