CE cables are used for general purpose power distribution in wet or dry locations, installed in air, in conduit or duct, or directly buried.

IEC 60502-1

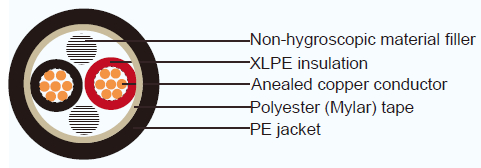

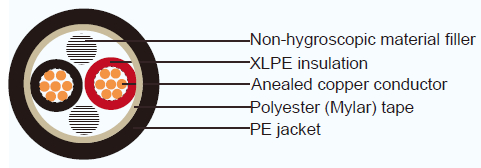

Conductor: Circle or circle compacted stranded annealed copper wires

Insulation: Cross-linked polyethylene(XLPE)

Color

2-4 cores : Black, White, Red and Green

More than 4 cores : Black core with marking numbers

Filler : Non-hygroscopic material(optional)

Binding tape : Polyester (Mylar) tape (optional)

Sheath : Polyethylene(PE), Black color.(A special flame retardant sheath can be supplied).

Maximum conductor temperature 90°C

Circuit voltage not exceeding 600 volts

Test voltage 3500 volts

| NOMINAL SECTIONAL AREA | NO. OF WIRE | DIAMETER OF CONDUCTOR (APPROX.) | THICKNESS OF INSULATION | THICKNESS OF SHEATH | OVERALL DIAMETER (APPROX.) | MAXIMUM DC. RESISTANCE OF CDR. AT 20°C | CABLE WEIGHT (APPROX.) |

|---|---|---|---|---|---|---|---|

| MM² | MM | MM | MM | MM | OHM / KM | KG / KM | |

| 1 core | |||||||

| 1.5 | 7/0.53 | 1.59 | 0.7 | 1.4 | 6.3 | 12.1 | 40 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.4 | 6.7 | 7.41 | 55 |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.4 | 7.2 | 4.61 | 70 |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.4 | 7.8 | 3.08 | 90 |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.4 | 9.4 | 1.83 | 150 |

| 16 | compacted | 4.7 | 0.7 | 1.4 | 10.0 | 1.15 | 180 |

| 25 | compacted | 5.9 | 0.9 | 1.4 | 12.0 | 0.727 | 280 |

| 35 | compacted | 6.9 | 0.9 | 1.4 | 13.0 | 0.524 | 370 |

| 50 | compacted | 8.1 | 1.0 | 1.4 | 14.5 | 0.387 | 480 |

| 70 | compacted | 9.8 | 1.1 | 1.4 | 16.0 | 0.268 | 680 |

| 95 | compacted | 11.4 | 1.1 | 1.5 | 18.5 | 0.193 | 920 |

| 120 | compacted | 12.9 | 1.2 | 1.5 | 20 | 0.153 | 1,150 |

| 150 | compacted | 14.4 | 1.4 | 1.6 | 22 | 0.124 | 1,420 |

| 185 | compacted | 15.9 | 1.6 | 1.6 | 24 | 0.0991 | 1,770 |

| 240 | compacted | 18.3 | 1.7 | 1.7 | 27 | 0.0754 | 2,310 |

| 300 | compacted | 20.5 | 1.8 | 1.8 | 30 | 0.0601 | 2,880 |

| 400 | * | 23.2 | 2.0 | 1.9 | 34 | 0.0470 | 3,680 |

| 500 | * | 26.4 | 2.2 | 2.0 | 37 | 0.0366 | 4,710 |

| 630 | * | 30.2 | 2.4 | 2.2 | 42 | 0.0283 | 6,060 |

| 2 cores | |||||||

| 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 11.0 | 12.1 | 90 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 12.0 | 7.41 | 120 |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 13.0 | 4.61 | 160 |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 14.0 | 3.08 | 210 |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 17.0 | 1.83 | 290 |

| 16 | compacted | 4.7 | 0.7 | 1.8 | 18.5 | 1.15 | 400 |

| 25 | compacted | 5.9 | 0.9 | 1.8 | 22.0 | 0.727 | 600 |

| 35 | compacted | 6.9 | 0.9 | 1.8 | 24.0 | 0.524 | 820 |

| 50 | compacted | 8.1 | 1.0 | 1.8 | 27 | 0.387 | 1,080 |

| 70 | compacted | 9.8 | 1.1 | 1.8 | 31 | 0.268 | 1,520 |

| 95 | compacted | 11.4 | 1.1 | 1.9 | 35 | 0.193 | 2,070 |

| 120 | compacted | 12.9 | 1.2 | 2.0 | 38 | 0.153 | 2,550 |

| 150 | compacted | 14.4 | 1.4 | 2.2 | 43 | 0.124 | 3,160 |

| 185 | compacted | 15.9 | 1.6 | 2.3 | 47 | 0.0991 | 3,940 |

| 240 | compacted | 18.3 | 1.7 | 2.5 | 53 | 0.0754 | 5,130 |

| 300 | compacted | 20.5 | 1.8 | 2.6 | 58 | 0.0601 | 6,380 |

| 3 cores | |||||||

| 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 11.5 | 12.1 | 120 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 12.5 | 7.41 | 150 |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 13.5 | 4.61 | 210 |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 14.5 | 3.08 | 280 |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 18.0 | 1.83 | 410 |

| 16 | compacted | 4.7 | 0.7 | 1.8 | 19.5 | 1.15 | 560 |

| 25 | compacted | 5.9 | 0.9 | 1.8 | 23 | 0.727 | 840 |

| 35 | compacted | 6.9 | 0.9 | 1.8 | 25 | 0.524 | 1,140 |

| 50 | compacted | 8.1 | 1.0 | 1.8 | 29 | 0.387 | 1,480 |

| 70 | compacted | 9.8 | 1.1 | 1.9 | 33 | 0.268 | 2,100 |

| 95 | compacted | 11.4 | 1.1 | 2.0 | 37 | 0.193 | 2,850 |

| 120 | compacted | 12.9 | 1.2 | 2.1 | 41 | 0.153 | 3,640 |

| 150 | compacted | 14.4 | 1.4 | 2.3 | 46 | 0.124 | 4,500 |

| 185 | compacted | 15.9 | 1.6 | 2.4 | 50 | 0.0991 | 5,630 |

| 240 | compacted | 18.3 | 1.7 | 2.6 | 57 | 0.0754 | 7,330 |

| 300 | compacted | 20.5 | 1.8 | 2.7 | 62 | 0.0601 | 9,110 |

| 4 cores | |||||||

| 1.5 | 7/0.53 | 1.59 | 0.7 | 1.8 | 12.5 | 12.1 | 140 |

| 2.5 | 7/0.67 | 2.01 | 0.7 | 1.8 | 13.5 | 7.41 | 190 |

| 4 | 7/0.85 | 2.55 | 0.7 | 1.8 | 14.5 | 4.61 | 260 |

| 6 | 7/1.04 | 3.12 | 0.7 | 1.8 | 16.0 | 3.08 | 340 |

| 10 | 7/1.35 | 4.05 | 0.7 | 1.8 | 20 | 1.83 | 530 |

| 16 | compacted | 4.7 | 0.7 | 1.8 | 22 | 1.15 | 730 |

| 25 | compacted | 5.9 | 0.9 | 1.8 | 26 | 0.727 | 1,110 |

| 35 | compacted | 6.9 | 0.9 | 1.8 | 28 | 0.524 | 1,480 |

| 50 | compacted | 8.1 | 1.0 | 1.9 | 32 | 0.387 | 1,970 |

| 70 | compacted | 9.8 | 1.1 | 2.0 | 36 | 0.268 | 2,820 |

| 95 | compacted | 11.4 | 1.1 | 2.1 | 42 | 0.193 | 3,830 |

| 120 | compacted | 12.9 | 1.2 | 2.3 | 46 | 0.153 | 4,810 |

| 150 | compacted | 14.4 | 1.4 | 2.4 | 51 | 0.124 | 5,940 |

| 185 | compacted | 15.9 | 1.6 | 2.6 | 56 | 0.0991 | 7,430 |

| 240 | compacted | 18.3 | 1.7 | 2.8 | 63 | 0.0754 | 9,670 |

| 300 | compacted | 20.5 | 1.8 | 3.0 | 70 | 0.0601 | 12,040 |