| Industrial Cables | |||

Industrial Cables Single Core Fixed Wiring Cable

Industrial Cables Single Core Fixed Wiring Cable

6491X/6491X HR to BS 6004

Application and Description

6491X/6491X HR to BS 6004 cables are designed for use as fixed wiring in domestic, Industrial power and lighting applications

such as light fittings, appliances, switchgear and control gear, they can be used in conduit or trunking

or surface mounted when used as an earth. 6491X is equivalent to H05V-U/H07V-U/H07V-R.The heatresistant

version is ideal for use in installation which are subject to direct contact with high temperature

equipments (e.g. varnishing machines and drying towers etc.).

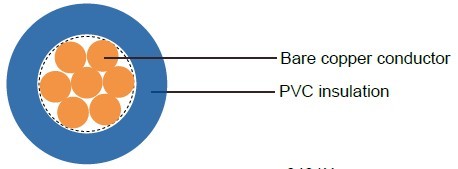

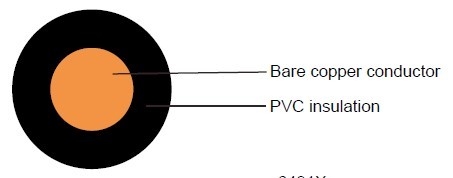

Cable Construction

Bare copper made of solid/strands conductor

Solid to BS 6360 Class 1 or IEC 60228 Class 1(H05V-U/H07V-U)

Stranding to BS 6360 Class 2 or IEC 60228 Class 2(H07V-R.)

Special PVC TI1/TI3(for 6491X HR ) core insulation

H05V-U (20, 18 & 17 AWG)

H07V-U (16 AWG and Larger)

Core Identification

Green/Yellow, Black, Blue, Brown, Red, White, Grey, Violet

Technical Characteristics

Working voltage: 300/500 volts(H05V-R), 450/750 volts(H07V-U/H07V-R)

Test voltage: 2000 volts(H05V-R), 2500 volts(H07V-U/H07V-R)

Minimum bending radius: Up to 10mm²: 3xoverall diameter

10mm² to 25mm²: 4xoverall diameter

Above 25mm²: 5xoverall diameter

Operating temperature: -0º C to +70º C/105 º C(for 6491X HR)

Short circuit temperature: +160º C

Flame retardant: IEC 60332.1

Insulation resistance: 10 MΩxkm

Cable Parameter

| AWG (No of Strands/ Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area #xmm² |

Nominal Thickness of Insulation mm |

Nominal Overall Diameter mm |

Nominal Copper Weight kg/km | Nominal Weight kg/km |

| H05V-U | |||||

| 20 | 1x0.5 | 0.6 | 2.1 | 4.8 | 9 |

| 18 | 1x0.75 | 0.6 | 2.2 | 7.2 | 11 |

| 17 | 1x1 | 0.6 | 2.4 | 9.6 | 14 |

| H07V-U | |||||

| 16 | 1x1.5 | 0.7 | 2.9 | 14.4 | 21 |

| 14 | 1x2.5 | 0.8 | 3.5 | 24 | 33 |

| 12 | 1x4 | 0.8 | 3.9 | 38.0 | 49 |

| 10 | 1x6 | 0.8 | 4.5 | 58.0 | 69 |

| 8 | 1x10 | 1.0 | 5.7 | 96 | 115 |

| H07V-R | |||||

| 16(7/24) | 1x1.5 | 0.7 | 3.0 | 14.4 | 23 |

| 14(7/22) | 1x2.5 | 0.8 | 3.6 | 24 | 35 |

| 12(7/20) | 1x4 | 0.8 | 4.2 | 39 | 51 |

| 10(7/18) | 1x6 | 0.8 | 4.7 | 58 | 71 |

| 8(7/16) | 1x10 | 1 | 6.1 | 96 | 120 |

| 6(7/14) | 1x16 | 1 | 7.2 | 154 | 170 |

| 4(7/12) | 1x25 | 1.2 | 8.4 | 240 | 260 |

| 2(7/10) | 1x35 | 1.2 | 9.5 | 336 | 350 |

| 1(19/13) | 1x50 | 1.4 | 11.3 | 480 | 480 |

| 2/0(19/11) | 1x70 | 1.4 | 12.6 | 672 | 680 |

| 3/0(19/10) | 1x95 | 1.6 | 14.7 | 912 | 930 |

| 4/0(37/12) | 1x120 | 1.6 | 16.2 | 1152 | 1160 |

| 300MCM(37/11) | 1x150 | 1.8 | 18.1 | 1440 | 1430 |

| 350MCM(37/10) | 1x185 | 2.0 | 20.2 | 1776 | 1780 |

| 500MCM(61/11) | 1x240 | 2.2 | 22.9 | 2304 | 2360 |

| (61/10) | 1x300 | 2.4 | 24.5 | 2980 | 2940 |

| (61/9) | 1x400 | 2.6 | 27.5 | 3765 | 3740 |